Published by: Alan Ashworth, Akron Beacon Journal

On Massillon Road in Green, some pretty high-tech, ’70s sci-fi stuff is going on at Surgere.

There are no flying cars or cyborg hands in a glass case, but its inventory tracking capabilities are the stuff of 1975 speculation that’s become 2023 reality.

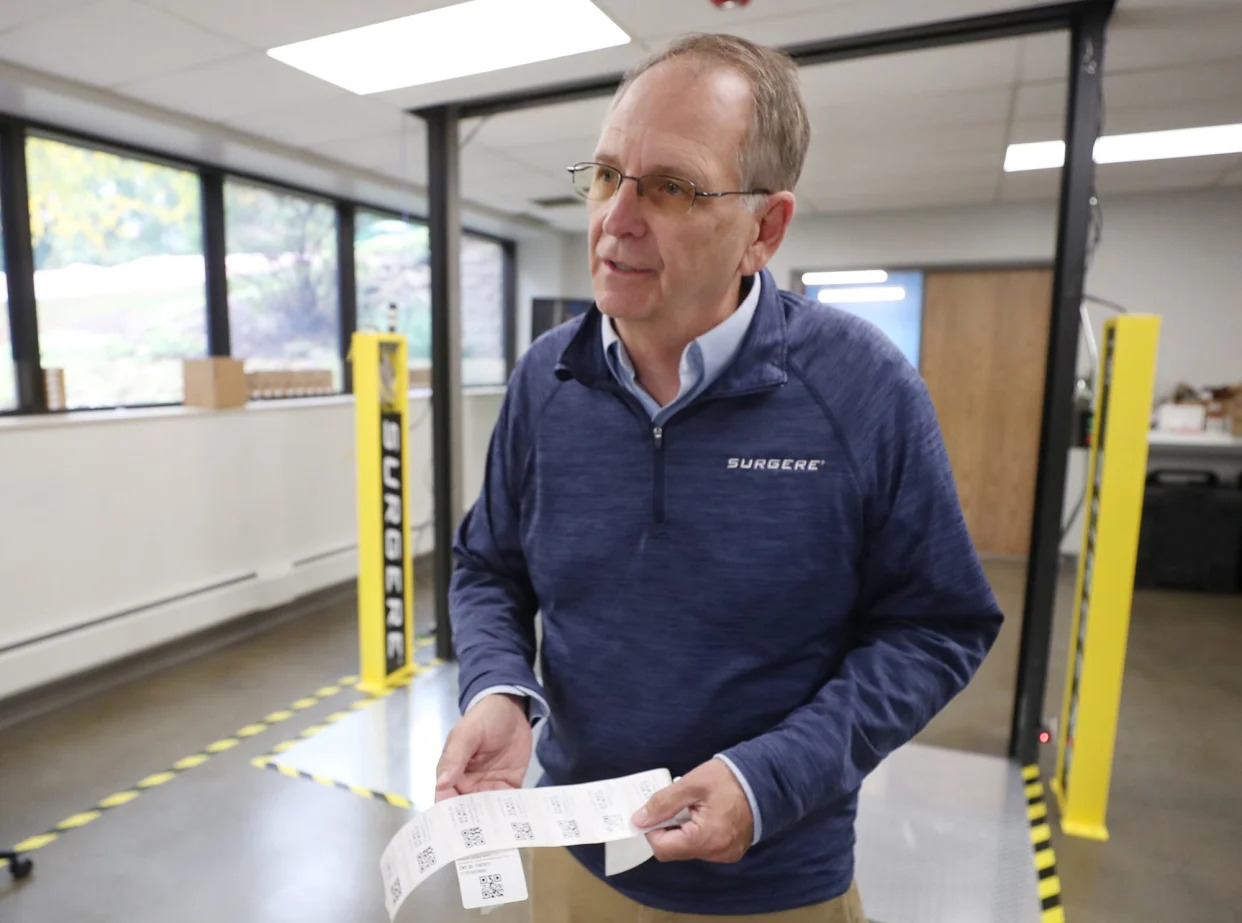

The company, founded in 2004 at CEO William Wappler‘s kitchen table, has evolved from a packaging consultant to a supply chain powerhouse.

From its headquarters building visible from Interstate 77, Surgere keeps track of inventory around the world for thousands of clients. At any second, the company knows where that ECM in Mexico is stashed, where that valve was misplaced in Southeast Asia and when the traction motor went on the move in Europe.

The company works with some of the world’s largest manufacturers, keeping track of inventory down to the widget on a corner shelf in the broom closet.

Surgere works with industry giants like Toyota and Honda

It does so with a tracking accuracy touted by Director of Market Intelligence Michael Schwabe as the industry’s best.

“When we say 99.9% accuracy, we have the data to back it up,” he said.

Surgere’s client list is impressive: Toyota, Honda, Caterpillar, Cummins among them.

It has nearly 2,000 clients in the “automotive space,” according to the company’s website.

15 billion transactions a month, 1,000 a second

“We’re manufacturing supply chain focused,” Surgere President Charles Dressler said in a recent interview at the company. “We’re collecting about 15 billion transactions on a monthly basis. We can read 1,000 of them a second.”

Dressler said the company anticipates it will double in size in the next two to three years.

“We are the dominant player in … automotive and industrial manufacturing,” he said.

Currently, the company has more than 75 employees, and that number keeps growing.

In recent years, it has shifted its software development effort from 90% offshore to 90% Northeast Ohio, Dressler said.

“We believe we can serve our customers better by having our people close at home,” he said. “… We have access to a great technological base in Northeast Ohio.”

Software that integrates current, emerging technologies

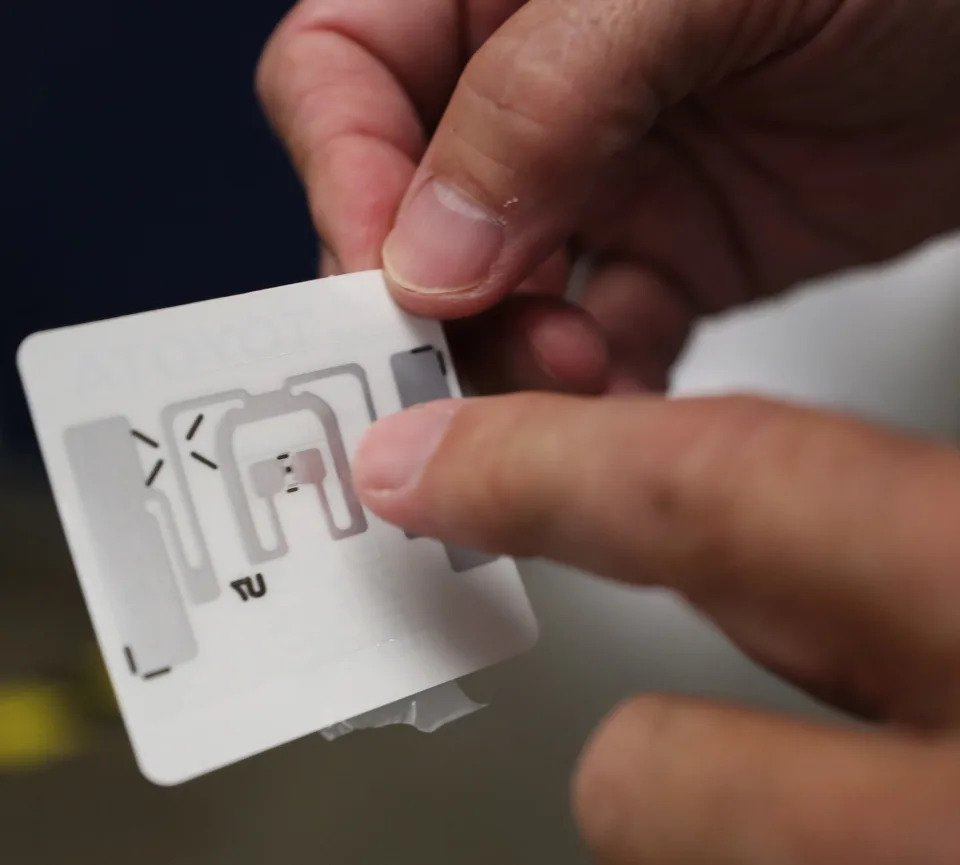

The Green company uses a proprietary software that’s able to integrate data it receives from RFID chips and other tracking technology to keep tabs on its clients’ inventory.

The company, Dressler said, can supply a multi-layered approach if needed, using GPS, Bluetooth and Ultra Wideband technology.

At its headquarters on Massillon Road, a lineup of video screens display on-time movement and charted information from around the world.

The website puts it this way: Interius provides “always-on access to your supply chain metrics, reports and insights that provide real-time information and alerts for exactly the intelligence you need.”

Surgere touts the software’s flexibility, with applications for transportation and distribution, production control and sustainability.

The software is programmed and updated by its software development team in Northeast Ohio.

AI chat, Surgere-style

Surgere has recently added an artificial intelligence, chatbot-like feature, which further streamlines the inventory control process and can help with decision-making and assigning routine tasks, said Dressler.

“Where that goes in 10 or 20 years, the sky’s the limit,” he said.

The integrated approach has put the company on a growth path, said Schwabe.

“Business is growing,” he said. “Business is good. Demand out there is very high.”

Leave a message for Alan Ashworth at 330-996-3859 or email him at aashworth@gannett.com. Follow him on Twitter at @newsalanbeaconj.

This article originally appeared on Akron Beacon Journal: ‘Sky’s the limit’: Inside supply chain wizard Surgere in Green